Photoacoustic Infrared, Highly Selective, Most Sensitive (1ppm), 24-hour Refrigerant Leak Detection and Notification Refrigerant Leak Detection and Monitoring Systems

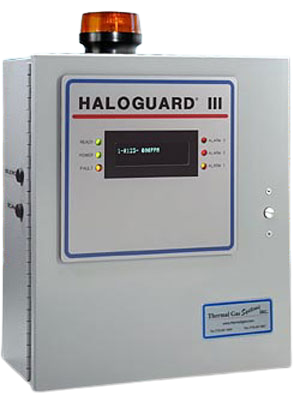

Haloguard III Photoacoustic Infrared, Multichannel, Multigas Detection and Notification Refrigerant Leak Detection and Monitoring Systems

Leak Detection and Monitoring Systems

The HALOGUARD ® III combines advanced microprocessor based digital signal processing and a wideband photoacoustic infrared cell to provide the newest, most advanced system for continuous monitoring of all refrigerant gases.

The HALOGUARD ® III monitors single or multiple, local and remote locations and provides notification when gas concentration reaches preset alarm levels. Up to 24 different gases may be monitored simultaneously by adding optional channel scanners and remote IR modules.

Alarm relays and analog outputs are designed to activate remote devices or to interface with an energy management (EMS)or building automation (BAS)system.

Features

- Simple installation

- Easy field calibration

- Up to 500 ft. sample draw

- Three user alarms adjustable between 50 ppm &100% of scale

- LCD shows PPM Concentration, Alarm, Test, Reset and Fault Diagnostics

- Three flashing alarm LEDs

- Fault, Ready & Power ON/OFF LEDs

- Analog output for BAS/EMS interface or data logging

- Four alarm relays for ventilation, damper or remote notification

- Alarm Test & Reset / Silence push buttons

- High-intensity audible alarm

- Rugged enclosure

Options & Accessories

- 2,4 or 8 channel scanner

- Remote IR module

- Amber strobe light alarm

- Remote strobe light & horn alarms

- Gas calibration kit

- NEMA 4/12 enclosure

- Oxygen depletion sensor

Specifications

| Technology | Photoacoustic Infrared |

| Electrical Supply | 115-230v, 50-60 Hz, 65W |

| Fuse | 3A/240V, fast acting |

| Output Signal | Std: 4x5A, dry contact relay SPDT Opt: 7x5A, dry contact relay SPDT Opt: 0-5VDC, 4-20mA analog |

| Sensitivity | 20 ppm |

| Resolution | 1 ppm |

| Measuring Range | 0-1000 ppm all refrigerants |

| Response Time | <1 minute per channel |

| Clearing Time | <3 minutes per channel |

| Maximum Sample Point Tubing Length |

150′ with standard performance 500′ optional where slower response is acceptable |

| Operating Conditions | 30°F to +120°F non-condensing |

| Enclosure: | Std: NEMA 250, 20 lbs. Opt: NEMA 4/12, 25 lbs. |

| Sample Rate | 1.0 lpm |

| Listed to UL 3111-1 and CAN/CSA-C22.2 No. 1010.1-92 | |

Sensor element is unconditionally guaranteed for one year from the date of shipment. Any sensors found defective in that period will be replaced free of charge.

Documents Available for Download (click for complete listing)